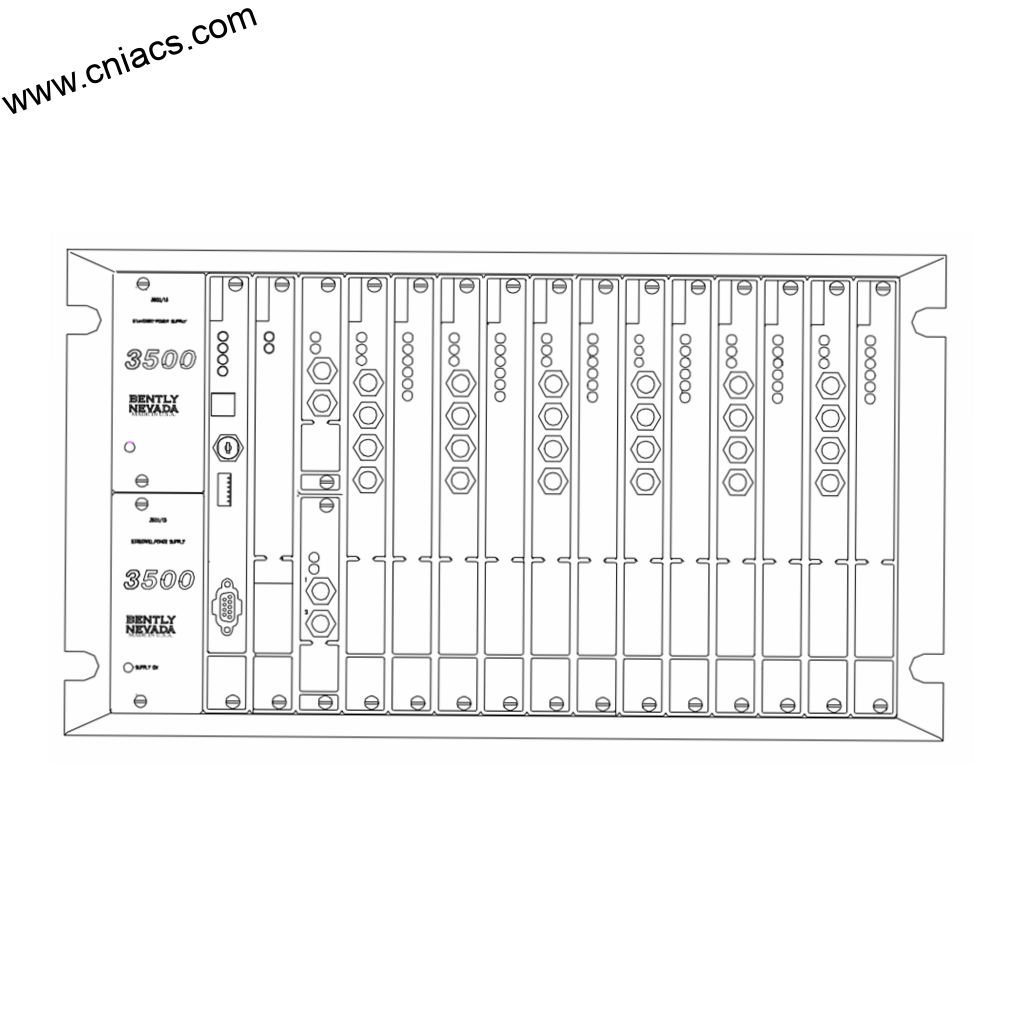

BENTLY Nevada 3500/22M, 138607-01 Transient Data Interface Module for Industrial Control Systems

Introducing the BENTLY Nevada 3500/22M, 138607-01 – an advanced monitoring solution that delivers exceptional performance and reliability for industrial applications. Renowned for its precision and versatility, this model stands out in the extensive range of BENTLY automation products, catering to a variety of needs in the field of condition monitoring and asset health management.

Key Technical Features

The BENTLY Nevada 3500/22M, 138607-01 boasts an array of cutting-edge technical features designed to enhance operational efficiency and ensure optimal performance. This model is equipped with advanced vibration monitoring capabilities, providing detailed insights into the condition of rotating machinery. With its high-frequency response, it captures critical data points, allowing for accurate diagnostics and predictive maintenance.

One of the standout features of the 3500/22M is its ability to support multiple input channels, enabling simultaneous monitoring of various machinery elements. The unit is designed to accommodate vibration, temperature, and speed inputs, making it a versatile choice for diverse applications. Additionally, the BENTLY Nevada 3500/22M utilizes advanced signal processing algorithms to filter noise and improve measurement accuracy, ensuring you receive reliable data to inform your maintenance decisions.

The system is also compatible with the BENTLY Nevada System 1 software, which facilitates comprehensive data analysis and reporting. This integration allows users to visualize trends, generate alerts for abnormal conditions, and make informed decisions based on real-time data. The rugged design of the 3500/22M ensures it performs reliably even in challenging environments, making it suitable for industries such as oil and gas, power generation, and manufacturing.

Usage Scenarios

The BENTLY Nevada 3500/22M, 138607-01 is engineered for a wide range of usage scenarios. In the oil and gas sector, it plays a crucial role in monitoring pumps, compressors, and turbines, helping to prevent costly downtime and equipment failures. Its ability to detect early signs of wear and tear allows operators to schedule maintenance proactively, ultimately extending equipment life.

In power generation facilities, the 3500/22M is essential for monitoring critical machinery such as generators and turbines. By providing real-time data on vibration levels and overall machine health, it enables operators to optimize performance and ensure consistent energy output. Additionally, in manufacturing environments, the unit can monitor conveyor systems, motors, and other rotating equipment, ensuring smooth operations and minimizing the risk of breakdowns.

The versatility of the BENTLY Nevada 350

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 3500/22M, 138607-01 boasts an array of cutting-edge technical features designed to enhance operational efficiency and ensure optimal performance. This model is equipped with advanced vibration monitoring capabilities, providing detailed insights into the condition of rotating machinery. With its high-frequency response, it captures critical data points, allowing for accurate diagnostics and predictive maintenance.

One of the standout features of the 3500/22M is its ability to support multiple input channels, enabling simultaneous monitoring of various machinery elements. The unit is designed to accommodate vibration, temperature, and speed inputs, making it a versatile choice for diverse applications. Additionally, the BENTLY Nevada 3500/22M utilizes advanced signal processing algorithms to filter noise and improve measurement accuracy, ensuring you receive reliable data to inform your maintenance decisions.

The system is also compatible with the BENTLY Nevada System 1 software, which facilitates comprehensive data analysis and reporting. This integration allows users to visualize trends, generate alerts for abnormal conditions, and make informed decisions based on real-time data. The rugged design of the 3500/22M ensures it performs reliably even in challenging environments, making it suitable for industries such as oil and gas, power generation, and manufacturing.

Usage Scenarios

The BENTLY Nevada 3500/22M, 138607-01 is engineered for a wide range of usage scenarios. In the oil and gas sector, it plays a crucial role in monitoring pumps, compressors, and turbines, helping to prevent costly downtime and equipment failures. Its ability to detect early signs of wear and tear allows operators to schedule maintenance proactively, ultimately extending equipment life.

In power generation facilities, the 3500/22M is essential for monitoring critical machinery such as generators and turbines. By providing real-time data on vibration levels and overall machine health, it enables operators to optimize performance and ensure consistent energy output. Additionally, in manufacturing environments, the unit can monitor conveyor systems, motors, and other rotating equipment, ensuring smooth operations and minimizing the risk of breakdowns.

The versatility of the BENTLY Nevada 350

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

There are no reviews yet.