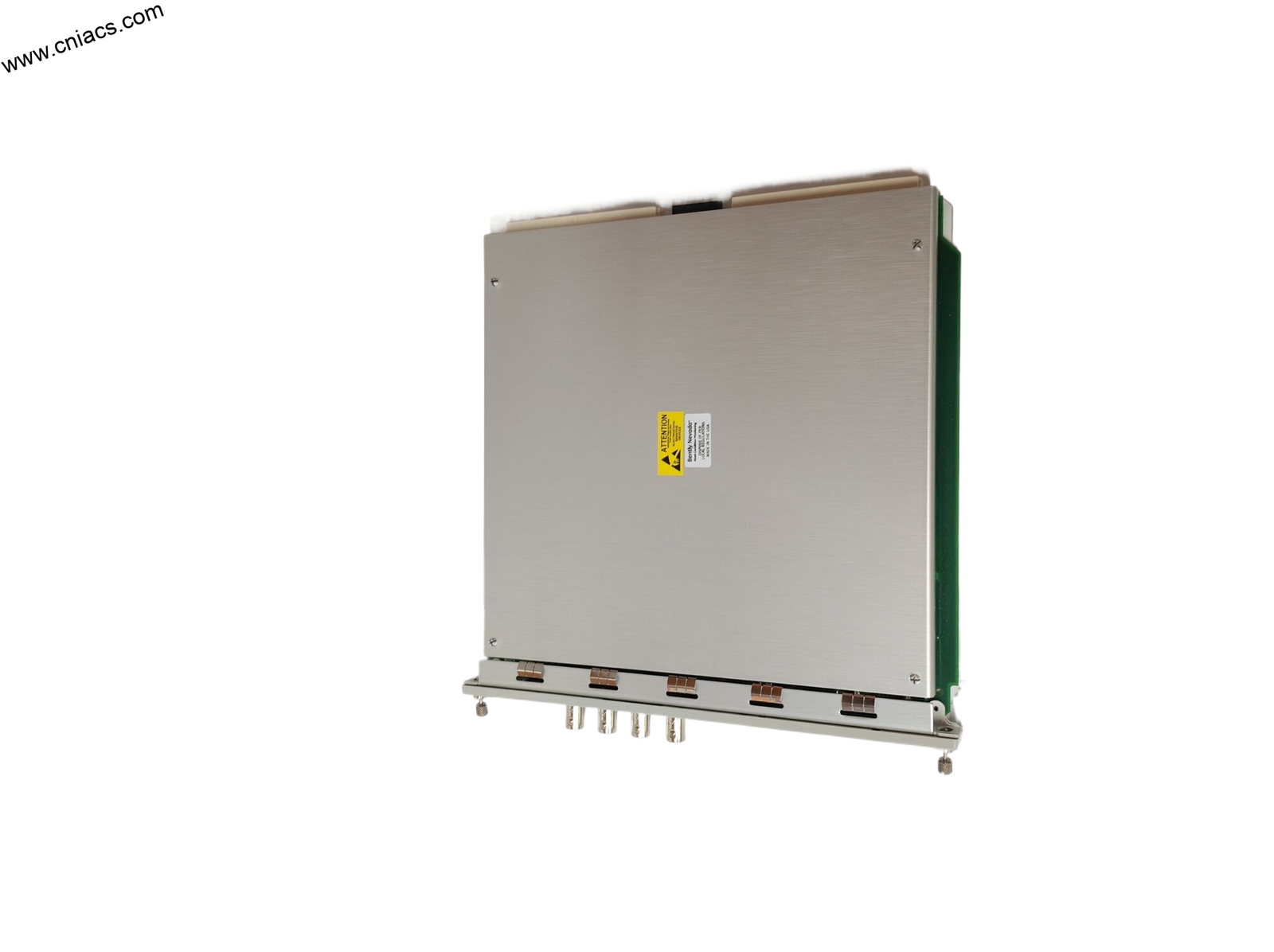

BENTLY Nevada 3500/53M Overspeed Detection Module Precision Safety Solution

Introducing the BENTLY Nevada 3500/53M Overspeed Detection Module, a vital component designed to enhance the safety and efficiency of your industrial operations. As part of the renowned BENTLY automation products line, this module offers cutting-edge technology and reliability, ensuring that your machinery operates within optimal parameters.

Key Technical Features

The BENTLY Nevada 3500/53M Overspeed Detection Module is engineered with state-of-the-art features that set it apart from competing products. With a robust design and superior functionality, this module ensures precise monitoring and control of rotating machinery. Key features include:

1. **Advanced Overspeed Detection**: The 3500/53M module accurately monitors the rotational speed of machinery, providing timely alerts to prevent overspeed conditions that could lead to catastrophic failures.

2. **Flexible Configuration Options**: This module supports various configurations, allowing integration with different systems and applications, making it suitable for a wide range of industrial environments.

3. **High Reliability and Durability**: Built with industrial-grade materials, the 3500/53M is designed to withstand harsh conditions, ensuring long-term reliability and performance in demanding environments.

4. **Real-Time Monitoring**: The module provides real-time data on speed conditions, enabling operators to make informed decisions quickly and effectively.

5. **User-Friendly Interface**: The intuitive interface simplifies installation and operation, allowing for easy integration into existing systems without the need for extensive training.

Usage Scenarios

The BENTLY Nevada 3500/53M Overspeed Detection Module is versatile and can be utilized in various industrial applications. Some typical usage scenarios include:

– **Turbine Monitoring**: In power generation facilities, the 3500/53M module is essential for monitoring turbine speeds, ensuring efficient operation and preventing damage caused by overspeed conditions.

– **Compressor Protection**: In oil and gas applications, the module safeguards compressors by detecting speed anomalies, thereby extending equipment life and optimizing performance.

– **Fan and Blower Systems**: The module is ideal for monitoring fans and blowers in HVAC systems, providing crucial data to maintain airflow efficiency and prevent overheating.

– **Pump Management**: In water treatment plants, the 3500/53M helps monitor pump speeds, ensuring proper operation and reducing the risk of equipment failure.

– **Manufacturing Operations**: In automotive and heavy machinery manufacturing, this module is employed to monitor and control the speed of various rotating equipment, contributing to consistent production quality

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 3500/53M Overspeed Detection Module is engineered with state-of-the-art features that set it apart from competing products. With a robust design and superior functionality, this module ensures precise monitoring and control of rotating machinery. Key features include:

1. **Advanced Overspeed Detection**: The 3500/53M module accurately monitors the rotational speed of machinery, providing timely alerts to prevent overspeed conditions that could lead to catastrophic failures.

2. **Flexible Configuration Options**: This module supports various configurations, allowing integration with different systems and applications, making it suitable for a wide range of industrial environments.

3. **High Reliability and Durability**: Built with industrial-grade materials, the 3500/53M is designed to withstand harsh conditions, ensuring long-term reliability and performance in demanding environments.

4. **Real-Time Monitoring**: The module provides real-time data on speed conditions, enabling operators to make informed decisions quickly and effectively.

5. **User-Friendly Interface**: The intuitive interface simplifies installation and operation, allowing for easy integration into existing systems without the need for extensive training.

Usage Scenarios

The BENTLY Nevada 3500/53M Overspeed Detection Module is versatile and can be utilized in various industrial applications. Some typical usage scenarios include:

– **Turbine Monitoring**: In power generation facilities, the 3500/53M module is essential for monitoring turbine speeds, ensuring efficient operation and preventing damage caused by overspeed conditions.

– **Compressor Protection**: In oil and gas applications, the module safeguards compressors by detecting speed anomalies, thereby extending equipment life and optimizing performance.

– **Fan and Blower Systems**: The module is ideal for monitoring fans and blowers in HVAC systems, providing crucial data to maintain airflow efficiency and prevent overheating.

– **Pump Management**: In water treatment plants, the 3500/53M helps monitor pump speeds, ensuring proper operation and reducing the risk of equipment failure.

– **Manufacturing Operations**: In automotive and heavy machinery manufacturing, this module is employed to monitor and control the speed of various rotating equipment, contributing to consistent production quality

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

-300x300.jpg?v=1739320885)

There are no reviews yet.