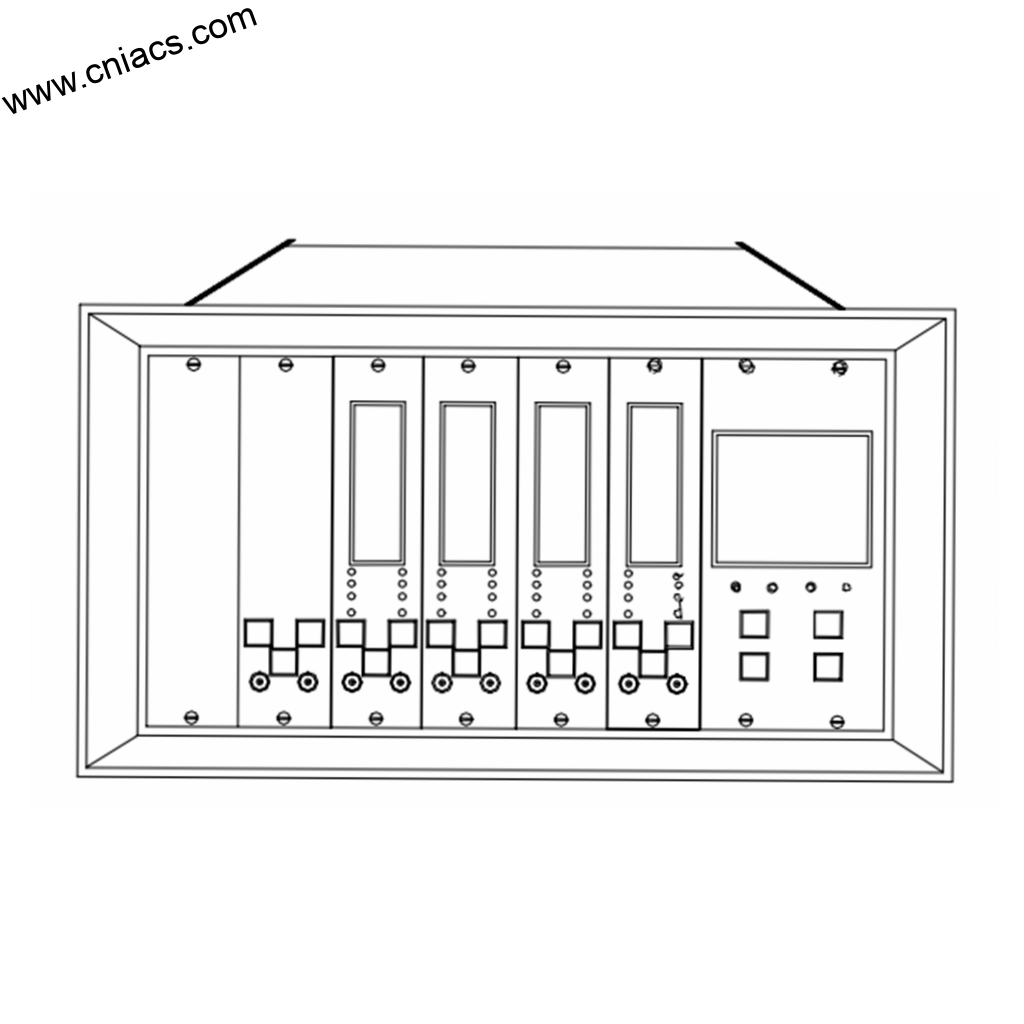

BENTLY Nevada 350500-00-00-00-11-00 Dynamic Pressure Charge Amplifier, Advanced Industrial Control Solution

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring Solutions

When it comes to ensuring the reliability and efficiency of critical machinery, the BENTLY Nevada series stands unrivaled in the realm of condition monitoring and asset management. Renowned for its robust design and cutting-edge technology, the BENTLY Nevada offers unparalleled performance and versatility to meet the demanding needs of various industries.

Key Technical Features

The BENTLY Nevada is engineered with state-of-the-art features that provide real-time data acquisition and analysis. Central to its design is the advanced vibration monitoring system that utilizes high-fidelity sensors, offering precise measurements of vibration, temperature, and other critical parameters. The system supports multiple input channels, enabling comprehensive monitoring of various machinery simultaneously.

One of the standout features of the BENTLY Nevada is its ability to integrate seamlessly with BENTLY automation products, enhancing the overall capabilities of your monitoring system. Its intuitive user interface and advanced analytics empower operators to quickly identify potential issues, reducing downtime and maintenance costs. With built-in diagnostic capabilities, the BENTLY Nevada not only monitors equipment health but also predicts failures before they occur, enabling proactive maintenance strategies.

The BENTLY Nevada is designed for a wide temperature range and harsh environmental conditions, making it ideal for use in power generation, oil and gas, mining, and manufacturing industries. Its rugged construction ensures durability, while its modular design allows for easy upgrades and expansions as your monitoring needs evolve.

Usage Scenarios

The BENTLY Nevada is perfectly suited for various applications across multiple industries. In power plants, it is essential for monitoring turbines, generators, and other critical equipment, ensuring efficient operations and minimizing downtime. In the oil and gas sector, the BENTLY Nevada monitors pumps, compressors, and drilling equipment, providing real-time insights that can prevent costly failures.

In manufacturing, the BENTLY Nevada plays a crucial role in maintaining the health of production machinery, from CNC machines to conveyor systems. By leveraging its predictive maintenance capabilities, manufacturers can optimize their operations and reduce the risk of unexpected breakdowns.

Additionally, the BENTLY Nevada is invaluable in the mining industry, where it monitors equipment such as crushers, conveyors, and hoists. Its ability to withstand harsh conditions ensures that operators receive accurate data even in the most challenging environments.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY product line, it becomes evident that its advanced features set it apart. For instance, while the BENT

The above parameters are for reference only. Please contact our technical team for precise selection.

When it comes to ensuring the reliability and efficiency of critical machinery, the BENTLY Nevada series stands unrivaled in the realm of condition monitoring and asset management. Renowned for its robust design and cutting-edge technology, the BENTLY Nevada offers unparalleled performance and versatility to meet the demanding needs of various industries.

Key Technical Features

The BENTLY Nevada is engineered with state-of-the-art features that provide real-time data acquisition and analysis. Central to its design is the advanced vibration monitoring system that utilizes high-fidelity sensors, offering precise measurements of vibration, temperature, and other critical parameters. The system supports multiple input channels, enabling comprehensive monitoring of various machinery simultaneously.

One of the standout features of the BENTLY Nevada is its ability to integrate seamlessly with BENTLY automation products, enhancing the overall capabilities of your monitoring system. Its intuitive user interface and advanced analytics empower operators to quickly identify potential issues, reducing downtime and maintenance costs. With built-in diagnostic capabilities, the BENTLY Nevada not only monitors equipment health but also predicts failures before they occur, enabling proactive maintenance strategies.

The BENTLY Nevada is designed for a wide temperature range and harsh environmental conditions, making it ideal for use in power generation, oil and gas, mining, and manufacturing industries. Its rugged construction ensures durability, while its modular design allows for easy upgrades and expansions as your monitoring needs evolve.

Usage Scenarios

The BENTLY Nevada is perfectly suited for various applications across multiple industries. In power plants, it is essential for monitoring turbines, generators, and other critical equipment, ensuring efficient operations and minimizing downtime. In the oil and gas sector, the BENTLY Nevada monitors pumps, compressors, and drilling equipment, providing real-time insights that can prevent costly failures.

In manufacturing, the BENTLY Nevada plays a crucial role in maintaining the health of production machinery, from CNC machines to conveyor systems. By leveraging its predictive maintenance capabilities, manufacturers can optimize their operations and reduce the risk of unexpected breakdowns.

Additionally, the BENTLY Nevada is invaluable in the mining industry, where it monitors equipment such as crushers, conveyors, and hoists. Its ability to withstand harsh conditions ensures that operators receive accurate data even in the most challenging environments.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY product line, it becomes evident that its advanced features set it apart. For instance, while the BENT

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

There are no reviews yet.