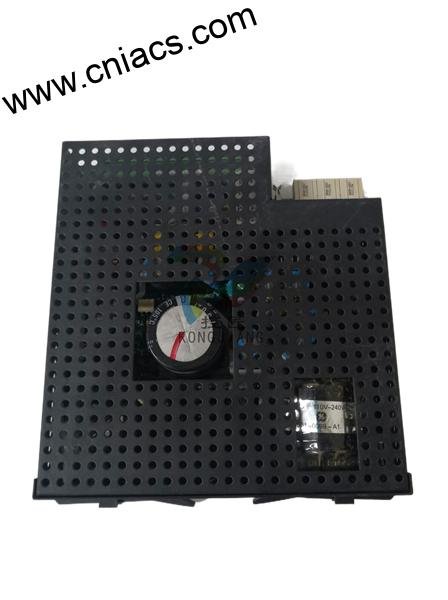

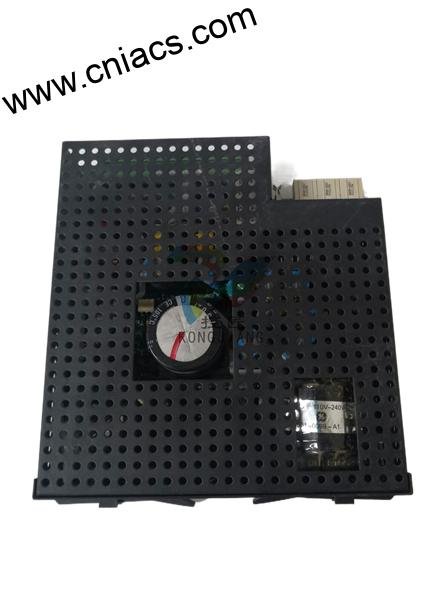

GE Fanuc IC3600SSKC1E1B Control Board Advanced Industrial Automation Solution

Introducing the GE Fanuc – a pinnacle of innovation and reliability in the realm of industrial automation. As part of the esteemed GE automation products lineup, the GE Fanuc model is engineered to meet the evolving demands of modern manufacturing and process control. This product description will delve into its key technical features, usage scenarios, comparisons with other models, and highlight related products to provide a comprehensive understanding of what makes the GE Fanuc a top choice for industries worldwide.

Key Technical Features

The GE Fanuc is characterized by its robust architecture, designed for high-performance operation in demanding environments. It features advanced processing capabilities, ensuring rapid data handling and real-time control. This model is equipped with a powerful CPU that enhances speed and efficiency, enabling seamless integration with other GE automation products.

One of the standout features of the GE Fanuc is its extensive I/O compatibility. It supports a wide range of input and output modules, allowing for flexible configuration tailored to specific application needs. This adaptability is further enhanced by its communication capabilities, supporting various protocols such as Ethernet/IP, Modbus, and more. This ensures that the GE Fanuc can easily connect with other devices and systems, facilitating streamlined automation processes.

The GE Fanuc also boasts enhanced diagnostic and troubleshooting capabilities. Built-in tools aid in predictive maintenance, helping to minimize downtime and extend the lifespan of the equipment. Its user-friendly interface simplifies operation and programming, making it accessible for engineers and technicians at all skill levels.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a myriad of applications across diverse industries. In manufacturing, it can be utilized for controlling assembly lines, monitoring production processes, and optimizing operational efficiency. Its ability to integrate with various sensors and actuators allows for precise control and automation of machinery.

In the energy sector, the GE Fanuc plays a critical role in process control and monitoring. Whether in power generation or distribution, its reliability ensures that systems operate smoothly, enhancing energy efficiency and reducing operational costs. Additionally, in the water and wastewater industry, the GE Fanuc can be employed for real-time monitoring and control of treatment processes, ensuring compliance with environmental regulations.

The GE Fanuc is also ideal for the automotive industry, where it can manage robotic systems, conveyor belts, and assembly processes. Its robust communication capabilities facilitate collaboration with other automation systems, enhancing overall productivity and efficiency.

Comparison with Other Models

When comparing the GE Fanuc to other models in the GE lineup, such as the GE IS220PPROS1B and GE IS215UCVEH2AB, it becomes evident that the GE Fanuc offers enhanced processing power and better I/O support. While the IS220PPROS1B is excellent for specific applications, the GE Fanuc's versatility and scalability make it a more comprehensive solution for a wider range of industrial needs.

In contrast to the GE IC697MDL250, which excels in specific control applications, the GE Fanuc's broader compatibility with various modules allows for easier adaptation to changing requirements. Its advanced diagnostic features also set it apart from models like the GE DS200TCQAG1BHF, providing users with greater insight into system performance and maintenance needs.

Related Models

For those interested in exploring additional options within the GE automation products portfolio, consider these related models:

1. GE IS200TBCIH1BBC – A robust controller designed for intricate applications.

2. GE CT7P70500470CW24 – A versatile I/O module with exceptional connectivity.

3. GE IS220PAICH2A – A powerful interface card for data processing and communication.

4. GE 369-HI-0-M-0-0-0 – A high-performance controller suitable for complex tasks.

5. GE IC693CPU374 – A reliable CPU known for its efficiency in industrial settings.

6. GE IS200TPROH1BBB – A controller with advanced processing capabilities.

7. GE IC660ELB912G – An I/O module that complements various GE automation systems.

8. GE DS200CTBAG1ADD – A digital output module that enhances control applications.

9. GE IC670MDL740J – Known for its high reliability in industrial environments.

10. GE IS200DSPXH1DBC – A sophisticated signal processing unit for advanced applications.

In conclusion, the GE Fanuc stands out as a premier choice in the GE automation products range, offering unmatched performance, flexibility, and reliability. Its advanced technical features make it suitable for a wide array of applications, from manufacturing to energy and automotive sectors. The model's ability to integrate seamlessly with other devices and systems, coupled with its user-friendly interface, ensures that it meets the demands of modern industrial environments. Whether you are looking to optimize production processes, enhance energy efficiency, or streamline operations, the GE Fanuc is designed to exceed expectations and drive success in your automation endeavors.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE Fanuc is characterized by its robust architecture, designed for high-performance operation in demanding environments. It features advanced processing capabilities, ensuring rapid data handling and real-time control. This model is equipped with a powerful CPU that enhances speed and efficiency, enabling seamless integration with other GE automation products.

One of the standout features of the GE Fanuc is its extensive I/O compatibility. It supports a wide range of input and output modules, allowing for flexible configuration tailored to specific application needs. This adaptability is further enhanced by its communication capabilities, supporting various protocols such as Ethernet/IP, Modbus, and more. This ensures that the GE Fanuc can easily connect with other devices and systems, facilitating streamlined automation processes.

The GE Fanuc also boasts enhanced diagnostic and troubleshooting capabilities. Built-in tools aid in predictive maintenance, helping to minimize downtime and extend the lifespan of the equipment. Its user-friendly interface simplifies operation and programming, making it accessible for engineers and technicians at all skill levels.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a myriad of applications across diverse industries. In manufacturing, it can be utilized for controlling assembly lines, monitoring production processes, and optimizing operational efficiency. Its ability to integrate with various sensors and actuators allows for precise control and automation of machinery.

In the energy sector, the GE Fanuc plays a critical role in process control and monitoring. Whether in power generation or distribution, its reliability ensures that systems operate smoothly, enhancing energy efficiency and reducing operational costs. Additionally, in the water and wastewater industry, the GE Fanuc can be employed for real-time monitoring and control of treatment processes, ensuring compliance with environmental regulations.

The GE Fanuc is also ideal for the automotive industry, where it can manage robotic systems, conveyor belts, and assembly processes. Its robust communication capabilities facilitate collaboration with other automation systems, enhancing overall productivity and efficiency.

Comparison with Other Models

When comparing the GE Fanuc to other models in the GE lineup, such as the GE IS220PPROS1B and GE IS215UCVEH2AB, it becomes evident that the GE Fanuc offers enhanced processing power and better I/O support. While the IS220PPROS1B is excellent for specific applications, the GE Fanuc's versatility and scalability make it a more comprehensive solution for a wider range of industrial needs.

In contrast to the GE IC697MDL250, which excels in specific control applications, the GE Fanuc's broader compatibility with various modules allows for easier adaptation to changing requirements. Its advanced diagnostic features also set it apart from models like the GE DS200TCQAG1BHF, providing users with greater insight into system performance and maintenance needs.

Related Models

For those interested in exploring additional options within the GE automation products portfolio, consider these related models:

1. GE IS200TBCIH1BBC – A robust controller designed for intricate applications.

2. GE CT7P70500470CW24 – A versatile I/O module with exceptional connectivity.

3. GE IS220PAICH2A – A powerful interface card for data processing and communication.

4. GE 369-HI-0-M-0-0-0 – A high-performance controller suitable for complex tasks.

5. GE IC693CPU374 – A reliable CPU known for its efficiency in industrial settings.

6. GE IS200TPROH1BBB – A controller with advanced processing capabilities.

7. GE IC660ELB912G – An I/O module that complements various GE automation systems.

8. GE DS200CTBAG1ADD – A digital output module that enhances control applications.

9. GE IC670MDL740J – Known for its high reliability in industrial environments.

10. GE IS200DSPXH1DBC – A sophisticated signal processing unit for advanced applications.

In conclusion, the GE Fanuc stands out as a premier choice in the GE automation products range, offering unmatched performance, flexibility, and reliability. Its advanced technical features make it suitable for a wide array of applications, from manufacturing to energy and automotive sectors. The model's ability to integrate seamlessly with other devices and systems, coupled with its user-friendly interface, ensures that it meets the demands of modern industrial environments. Whether you are looking to optimize production processes, enhance energy efficiency, or streamline operations, the GE Fanuc is designed to exceed expectations and drive success in your automation endeavors.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.